Size :

DN15 – DN200 (custom sizes available)End Connections :

Flanged, Threaded, or WeldedMaterial :

Cast Iron, Stainless Steel, or PVCTemperature Range :

-10°C to +120°CPressure Rating :

From 4 to 16 BarDesign Standards :

ANSI, DIN, JIS standards availableSuitable Medium :

Water, oil, acids, slurry, air...Operation :

Pneumatic, Electric, or Manual

The Weir type diaphragm valve is a type of valve under diaphragm valves. This is one of the most popular of all diaphragm valves. Weir type diaphragm valve has a raised saddle or lip where the diaphragm part presses to produce sealing action. Due to the raised lip, the level of diaphragm travel reduces from opening fully to a completely closed position. As such, the induced stress on the diaphragm due to closing the valve decreases.

The diaphragm is made of strong material making it suitable for high pressure and vacuum applications. Weir type diaphragm valves perform very well in control of fluid flow, throttling, and control of minute flow rates. Weir type diaphragm valves use a two-piece compressor to create a small opening at the valve center. Weir type diaphragm valves are often used to handle homogeneous and clean liquids and gases since contamination and viscous sludge can accumulate on the saddle. These valves can also work on hazardous, abrasive, and corrosive media.Weir Type Diaphragm Valve is specifically suited to handle corrosive and general applications, it permits the larger options of linings and diaphragm grades to be combined. Given the shorter valve stroke, it is the preferred option to fluoropolymers lining and the only design suiting to PTFE diaphragms.

CNM VALVE is the leading Weir Type Diaphragm Valve Manufacturer in China, our weir diaphragm valves allow for more diaphragm cycles with less running and downtime costs, its pocketless design avoids line fluid contamination. Weir valves are the option when flow control is required.

The weir type diaphragm valve utilizes a flexible diaphragm that is linked to a compressor. The compressor, in turn, is connected to a stem. When there is a need to increase the flow rate, the stem is raised. As the stem moves upward, it imparts the motion to the connected compressor. Consequently, the compressor also moves upward, causing the diaphragm to rise. This upward movement of the diaphragm results in an increased flow of fluid.

Conversely, to decrease the flow rate or completely halt the flow, the stem is turned and lowered. The downward motion of the stem is transmitted to the compressor, which then applies pressure on the diaphragm, causing it to move downward. This downward movement of the diaphragm either reduces the flow rate or completely shuts off the fluid flow.

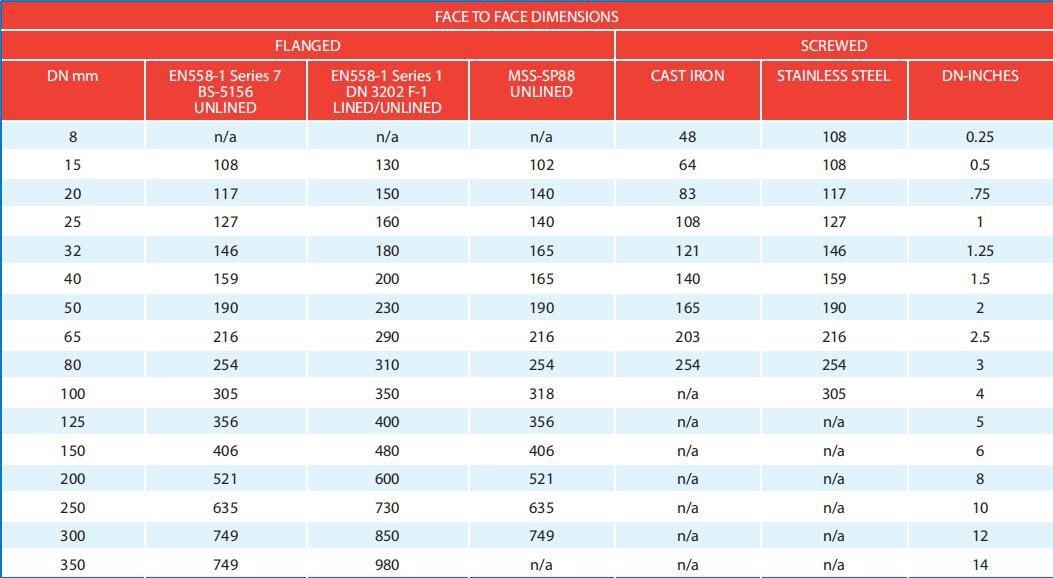

Dimensions of Weir Type Diaphragm Valve

Weir type diaphragm valves have many linings that help them to resist chemical damage.

These valves offer a bubble-tight service.

These valves are suitable for delivering hazardous and radioactive fluids.

Weir type diaphragm valves work well in viscous fluids.

They can be used in on-off and throttling flow applications.

1. Leakage:

Check if the valve is fully closed. Ensure that the diaphragm is in proper contact with the weir and forming a tight seal.

Inspect the diaphragm for any signs of damage, such as tears or cracks. Replace the diaphragm if necessary.

Verify that the valve body and seat surfaces are clean and free from debris or scale buildup that may hinder the sealing.

2. Diaphragm Failure:

Examine the diaphragm for signs of wear, fatigue, or chemical degradation. Replace the diaphragm if it appears damaged or worn out.

Ensure that the diaphragm is correctly installed, centered, and properly secured to the valve stem or compressor. Improper installation can lead to premature failure.

3. Sticking or Difficult Operation:

Check for any obstructions or debris that may be hindering the movement of the diaphragm. Clean the valve thoroughly and remove any blockages.

Inspect the valve stem or compressor for excessive wear or binding. Lubricate or replace the stem if necessary.

Verify that the actuator or control mechanism is functioning correctly and providing sufficient force for smooth operation.

4. Uneven Flow or Restricted Flow:

Examine the weir for any damage, buildup, or misalignment that could cause uneven flow patterns. Clean or repair the weir as needed.

Check for any obstructions in the valve body or seat that may be restricting the flow. Clean the valve thoroughly to remove any debris.

5. Excessive Wear:

Regularly inspect the valve components for signs of wear, such as erosion or corrosion. Replace worn-out parts promptly to prevent further damage.

Consider upgrading to a higher-quality diaphragm material or a more durable valve design if wear is a recurring issue.

Certificate:

Why choose CNM VALVE?

CNM Valve is committed to delivering superior quality products that meet international standards and specifications.We offer tailored solutions to meet your unique operational needs, including material selection, size, and actuator options.Our team of experts is available to provide installation support, troubleshooting, and maintenance advice.Get the best value for your investment with our cost-effective solutions.

For more information or to request a quote, please visit the CNM VALVE website or contact our sales team directly.

For inquiries or to place an order, please reach out to our team today!

Email: market@valvescenter.com

Phone: +86 138 6861 8624

Website: www.valvescenter.com

Copyright @2024 WuHu Cnm Valve Industry Co.,Ltd. All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported