Valve Installation and Maintenance Guide

Valves are indispensable and critical components in industrial equipment. Their performance stability directly impacts the operational efficiency and safety of the entire system. To ensure optimal valve performance, we provide the following installation and maintenance service guide

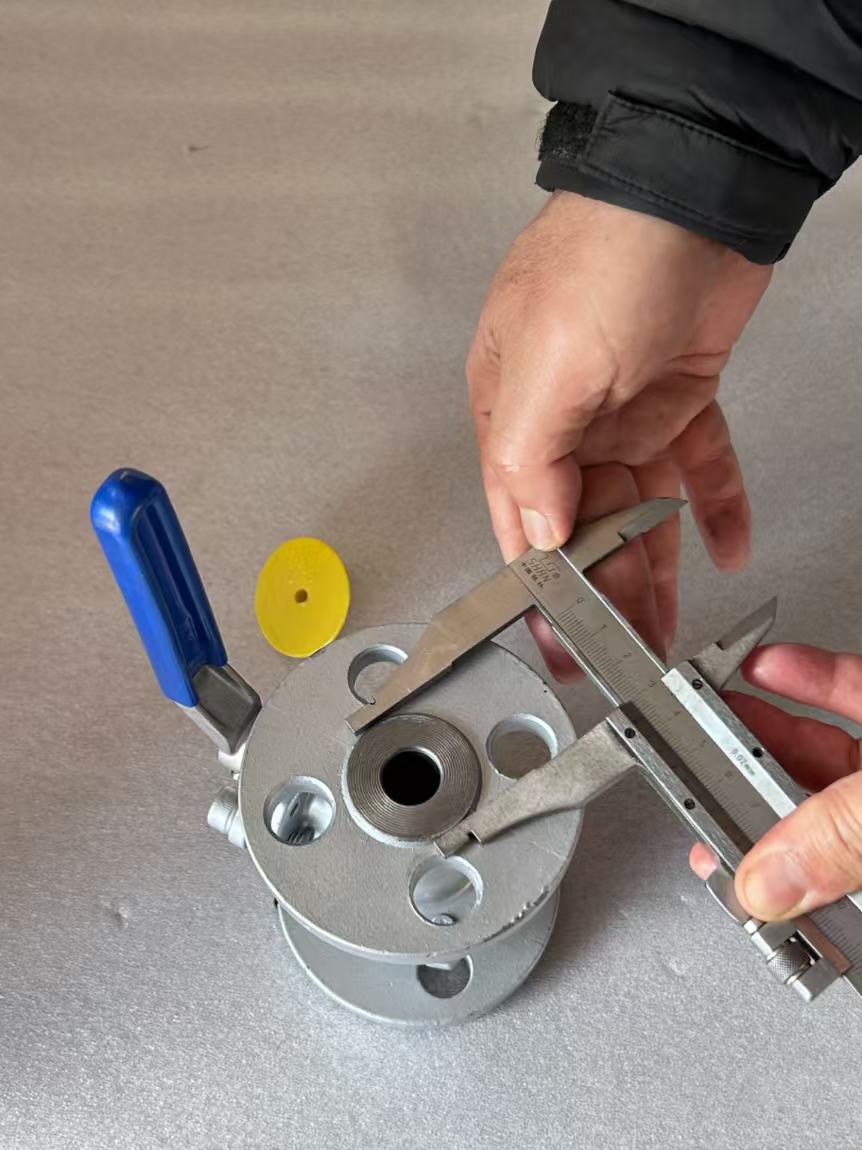

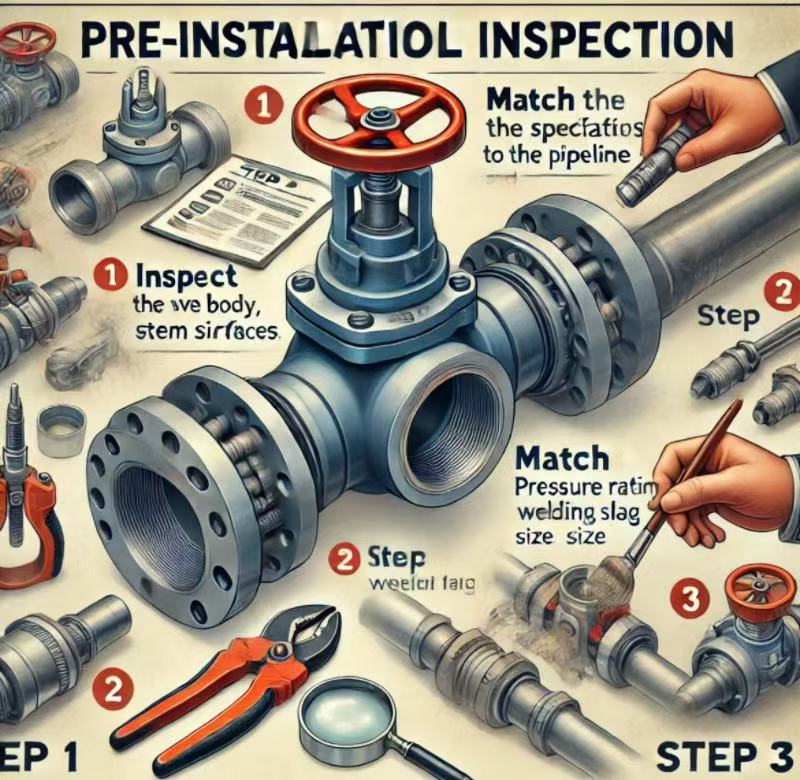

1. Pre-Installation Inspection

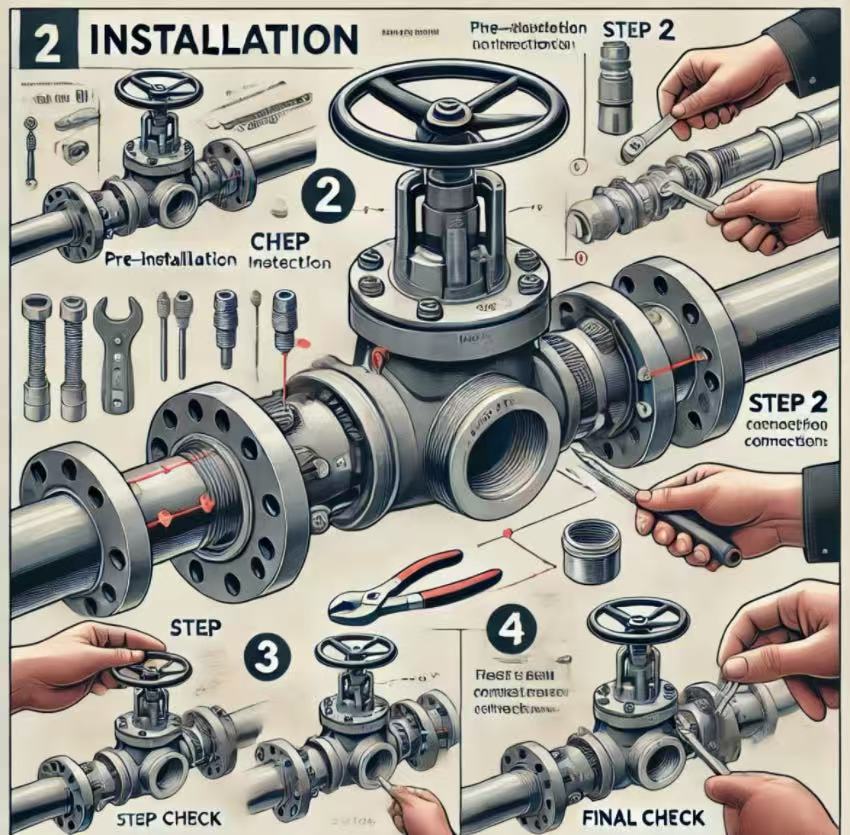

2. Proper Installation Steps

• Install the valve according to its operating direction and the flow direction of the medium.

• For threaded valves, apply sealing materials (such as PTFE tape) to prevent leaks.

• For flanged valves, tighten the bolts evenly to avoid uneven stress on the connecting surface.

3. Routine Maintenance

• Regular Cleaning: Clean the valve’s surface and remove internal deposits to keep the passage unobstructed.

• Stem Lubrication: For manual valves, periodically lubricate the valve stem to prevent jamming and corrosion.

• Seal Performance Check: Inspect the valve for leaks after closure and replace the sealing components if necessary.

4. Troubleshooting and Repairs

• Leakage Issues: Commonly caused by aging gaskets or packing; replace damaged components as needed.

• Valve Jamming: May result from foreign object blockage or bent stems; clean the valve or replace the stem if required.

• Operation Failure: Inspect the actuator to ensure proper functionality, and repair or replace it as necessary.

By performing regular maintenance and ensuring professional handling, you can extend the lifespan of your valves and maintain system reliability. For further assistance, please feel free to contact our technical team. We are here to provide comprehensive support.

Copyright @2024 WuHu Cnm Valve Industry Co.,Ltd. All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported