Size :

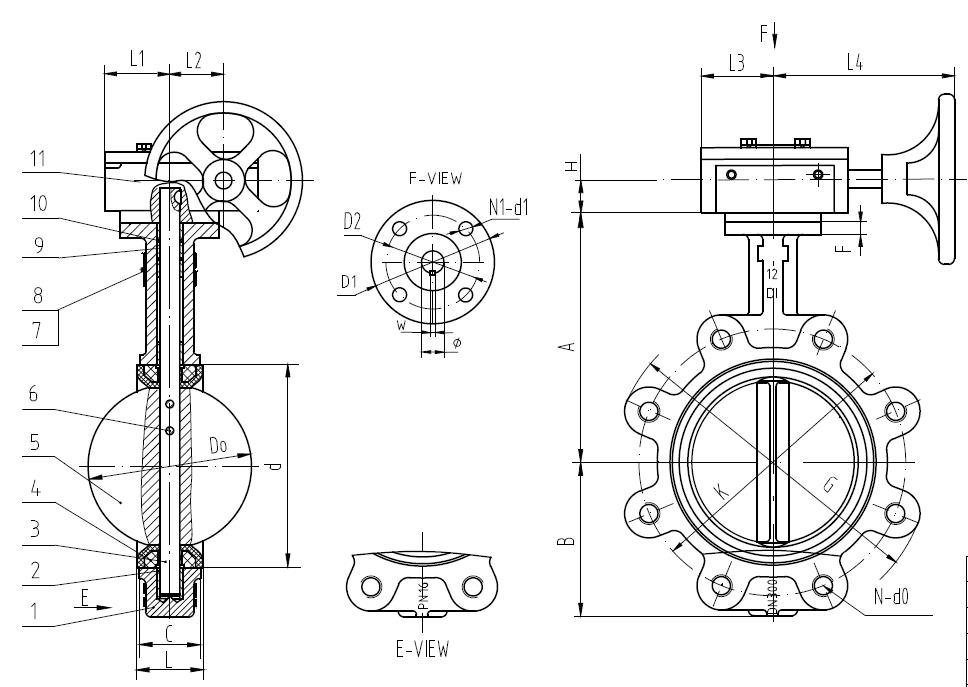

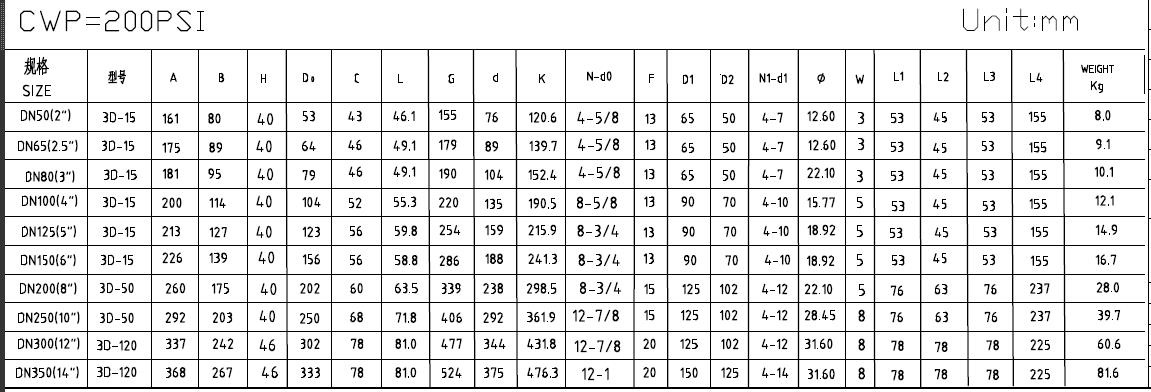

From DN50 to DN1600End Connections :

Lug TypeMaterial :

Cast iron, Ductile iron, Carbon Steel, Stainless SteelTemperature Range :

-20°C to 120°CPressure Rating :

Class 150 - Class 2500Design Standards :

API 6D, API 608Suitable Medium :

Oil, Gas, Water, ChemicalsOperation :

Manual or ActuatedQuick and easy installation: The Lug Butterfly Valve Soft Seal can be installed in a wafer configuration, which means that it can be quickly and easily mounted between two flanges, without the need for additional bolts or hardware.

Bi-directional sealing: The soft seal material used in the valve ensures that it can seal effectively in both directions, providing efficient flow control in applications where reverse flow is possible.

Low pressure drop: The design of the valve allows for a smooth and unobstructed flow path, resulting in minimal pressure drop across the valve, which can help to reduce energy costs.

Corrosion resistance: The valve is available in a range of materials, including stainless steel and high-performance polymers, which can provide excellent resistance to corrosion and other forms of chemical attack.

Automation capability: The valve is designed to accept an ISO 5211 mounting plate, which allows for easy attachment of pneumatic or electric actuators, making it suitable for use in automated process control applications.

Versatility: The valve can be used in a wide range of applications and industries, including water treatment, chemical processing, food and beverage production, and many others.

The valve is mainly used as a cut-off valve; it is suitable for transporting various corrosive, non On pipelines and containers of corrosive fluid media, it is used to regulate and cut off the flow of media.

The Difference Between a Lug and Wafer Butterfly Valve

The difference between the two valves lies in the material used for the seat and disc.

Lugs are usually made of ductile iron, while wafers are made from softer materials. Choosing between a lug and wafer butterfly valve requires considering the application and flow media.

Lug butterfly valves have threaded inserts on both sides of the valve body, making them suitable for systems with two sets of bolts without nuts. They are installed between two flanges, one with an internal thread, and their lug design allows for easy disconnection of the piping system post-installation. A lug butterfly valve typically lacks a spring or internal mechanism that could cause a leak.

In contrast, wafer-type butterfly valves are designed to withstand bi-directional pressure in fluid flow and prevent backflows in the system. They feature a tight-fitted seal, such as O-rings or gaskets, and are used with flat face valves. Composed of fewer materials, wafer butterfly valves are smaller and lighter and can be quickly opened and closed, making them ideal for various industrial applications.

Certificate:

Why choose CNM VALVE?

Our Lug Butterfly Valve Soft Seal can be tailored to meet specific project requirements.CNM Valve has years of experience manufacturing high-quality butterfly valves that meet industry standards and exceed customer expectations.With our robust quality control and customer support, you can trust CNM Valve for efficient, long-lasting valve solutions.

For more information or to request a quote, please visit the CNM VALVE website or contact our sales team directly.

For inquiries or to place an order, please reach out to our team today!

Email: market@valvescenter.com

Phone: +86 138 6861 8624

Website: www.valvescenter.com

Copyright @2024 WuHu Cnm Valve Industry Co.,Ltd. All Rights Reserved.

Sitemap

/ Blog

/ Xml

/ Privacy Policy

Network Supported

Network Supported