Plug valves are quarter-turn rotational valves that are used for on-off and throttling applications. They consist of a cylindrical or conical-shaped plug that rotates within the valve body to control the flow of fluids. The plug has a hole or port in the center that allows the fluid to pass through when it is aligned with the inlet and outlet ports. When the plug is rotated by 90 degrees, the port is perpendicular to the flow direction, blocking the fluid.

Plug valves have a simple design and are easy to operate, making them ideal for applications where quick and frequent operation is required. They are also versatile and can handle a wide range of fluids, pressures, and temperatures.

There are several types of plug valves available in the market, each designed for specific applications. There are three basic plug valve-types: the lubricated, nonlubricated, and soft-sealed fire safe. Let's take a look at some of the most common types:

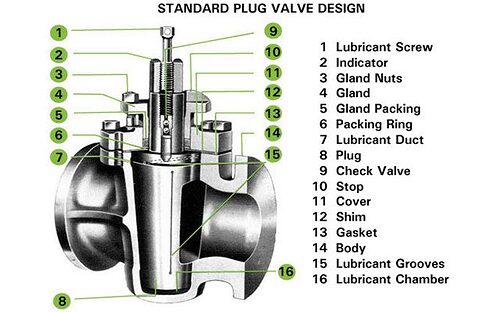

Lubricated plug valves are the most common type of plug valves and are suitable for a wide range of applications. These valves have a lubricant injected into the body cavity, which reduces the friction between the plug and the body. Lubricated plug valves have a longer life cycle and can handle higher pressures and temperatures compared to non-lubricated plug valves. Lubricated plug valves are commonly used in the oil and gas industry, chemical processing plants, and power generation facilities.

Non-lubricated plug valves are designed for applications where contamination of the fluid with lubricant is not acceptable. These valves have a hard, wear-resistant plug that can withstand high temperatures and pressures without the need for lubrication. Non-lubricated plug valves have a shorter life cycle compared to lubricated plug valves and require frequent maintenance. Non-lubricated plug valves are commonly used in applications that involve corrosive or abrasive fluids, such as wastewater treatment plants and mining operations.

Fire safety plug valves use a narrow-band primary sealing ring made of a flexible, elastic material (such as Teflon) in the ring between the plug and the body cavity to prevent leakage.

A fire safe soft seal valve also has a secondary metal-to-metal backup seal. This ensures a positive closing capability if the soft seal is damaged by fire. The maximum temperature limit of the valve is limited by the soft-seal material. Fire safety plug valves are a type of plug valve that is designed to prevent the spread of fire in industrial settings. These valves are commonly used in applications where flammable fluids or gases are present, such as oil and gas processing plants, chemical manufacturing facilities, and power generation plants.

Types of Check Valves And Their Applications

What are the Different Types of Water Valves?

Contact Us

Related Information

What is the standard API for gate valves?API 6D Ball Valve ManufacturersTrunnion Mounted Ball Valves Manufacturer5 Best Plug Valves Manufacturers and SuppliersDiaphragm ValveClass 300 LB Plug ValveFlanged End Ball Valves - API 6DLubricated VS. Non-Lubricated Plug Valves: What You Need to KnowControl Valves: Everything You Need to KnowAPI 600 Gate Valve ManufacturerTypes of Plug ValvesThe Difference between API 608 and API 6D Valve StandardTel:

+86 138 6861 8624

Tel(日本語対応):

+86 181 0553 1755

Email:

Email(日本語対応):

Keywords: Trunnion Mounted Ball Valves Manufacturer API 600 Gate Valve Manufacturer Types of Plug Valves Class 300 LB Plug Valve Lubricated VS. Non-Lubricated Plug Valves: What You Need to Know What is the standard API for gate valves? Control Valves: Everything You Need to Know 5 Best Plug Valves Manufacturers and Suppliers Diaphragm Valve API 6D Ball Valve Manufacturers Flanged End Ball Valves - API 6D The Difference between API 608 and API 6D Valve Standard

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More