Standard

Design: API594

Face to Face: API594

Testing Standard: API 598.

A Double Plate Check Valve is a type of non-return valve that is designed to prevent backflow in pipelines. It is sometimes referred to as a Dual Plate Check Valve or Duo Check Valve.

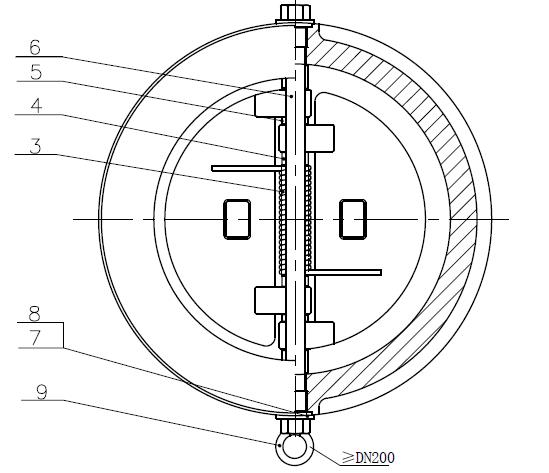

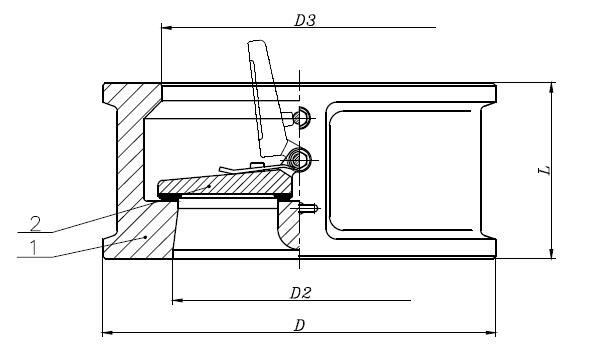

The valve consists of two spring-loaded plates that are hinged on a central pin. When there is flow in the forward direction, the plates are pushed open, allowing fluid to pass through. When the flow decreases or stops, the plates are closed by torsion spring action, preventing reverse flow.

Compared to traditional swing check valves and lift check valves, Double Plate Check Valves are generally stronger, lighter in weight, and smaller in size. They also offer the benefits of no water hammer and non-slam simultaneously, making them an efficient and effective choice for many applications.

Double Plate Check Valves are commonly used in industries such as oil and gas, water treatment, chemical processing, and power generation. They are available in a variety of materials, sizes, and designs to suit different pipeline applications.

| Parameter | Description |

|---|---|

| Type | Dual plate check valve |

| Function | Used to prevent backflow in piping systems |

| Body material | Cast iron, carbon steel, stainless steel, other alloys |

| Disc material | Stainless steel, other alloys |

| Stem material | Stainless steel, other alloys |

| Seat material | EPDM, NBR, Viton, PTFE, metal-to-metal |

| Size range | 1 inch to 60 inches |

| Pressure rating | ANSI class 150 to 2500, PN 10 to PN 420, JIS 10K to JIS 63K |

| Temperature range | -196°C to +815°C (-321°F to +1500°F) |

| End connections | Wafer, flanged |

| Face to Face | According to API 594 or DIN EN 558-1 standards |

| Installation | Horizontal or vertical |

| Maintenance | Minimal maintenance required |

| Advantages | Compact design, low pressure drop, quick response, low cost |

| Applications | Chemical, oil and gas, power generation, water treatment, etc. |

Light Weight thus easier handling and self supporting.

Light-weight discs for fast closing without backflow

Shock bumpers- extended cycle life of valve trim with minimal wear under the most severe services .

More compact & Structurally sound design.

Same valve can be installed horizontally or vertically.

Only Dual Plate Check Valve which can be installed for flow upside down due to spring assisted closure.

Low Pressure Drop and reduced Energy Loss irrespective of Pressure Ratings.

Lifting rings from DN 200

Tel:

+86 138 6861 8624

Tel(日本語対応):

+86 181 0553 1755

Email:

Email(日本語対応):

Keywords: Trunnion Mounted Ball Valves Manufacturer API 600 Gate Valve Manufacturer Types of Plug Valves Class 300 LB Plug Valve Lubricated VS. Non-Lubricated Plug Valves: What You Need to Know What is the standard API for gate valves? Control Valves: Everything You Need to Know 5 Best Plug Valves Manufacturers and Suppliers Diaphragm Valve API 6D Ball Valve Manufacturers Flanged End Ball Valves - API 6D The Difference between API 608 and API 6D Valve Standard

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More