Design & Manufacture comply with : API6D

Pressure & temperature comply with : B 16.34

Structure: ANSI B16.10

Testing Standard: API 598.

After passing the pressure test valve should be thoroughly cleaned, apply anti-rust oil, cover both ends of flange with seal.

CNM VALVE supplies 2" to 36" Trunnion Mounted Ball Valve that exceed industry standards. If you need it, please contact us immediately.

| Type Connection | Flanged MSS SP-44-1996 |

| Size | From 2" to 36" |

| Pressure | From 150LBS to 2500LBS |

| Material | Forged steel/A105,Stainless steel/CF8, Cast steel/WCB |

Discharge Device On Valve Body

According to user or device system requirement, discharge valve will be mounted on the body of ball valve. In case the two ends of valve ave been sealed. the pressure in valve will be released through the discharge valve on the body. Besides the function of DBB, this discharge valve also functions to rinse and blow out the deposits inside valve body.

Sulfide Stress Cracking Resistence

The Material exposed to fluid of our sulfur resisting ball valves including fastening components are all selected to NACE Mr 0175, and rigorous quality control and inspection is implemented in the manufacturing process to make our products conformed to the standard and suitable for vulcanizing conditions.

Corrosion Resistance

Corrosion allowance is let for the design of body thickness, the stem , fixed shaft, ball, seat and bottom cover of carbon steel valve are al chemical plated in surface to ASTM B733 and B656. Use of paint from international standard. to deal with all kinds of conditions.

Extension Bar Device

Extension device may be provided for buried ball valves, which include the extension of valve stem, greasing valve and discharge valve, As shown in the figure on the right, users shall specify the requirements and length to be extended (The length is generally the distance from the center of valve channer to the center of operating device.)

Please contact us for technical sheet and quotation !

1. Among various valves, the flow resistance of the trunnion ball valve is small. When the full-diameter ball valve is opened, the diameter of the ball channel, the valve body channel and the connecting pipe are equal and form a good diameter, and the medium can flow through almost without loss.

2. The trunnion ball valve can be fully closed and fully opened by rotating 90°, opening and closing quickly. Compared with the gate valve and globe valve of the same specification, the trunnion ball valve is small in size and light in weight, which is convenient for pipeline installation。

3. Better sealing performance: Trunnion Mounted Ball Valve has good sealing performance, so it can be used in high pressure operation.

Specification of Trunnion Mounted Ball Valve:

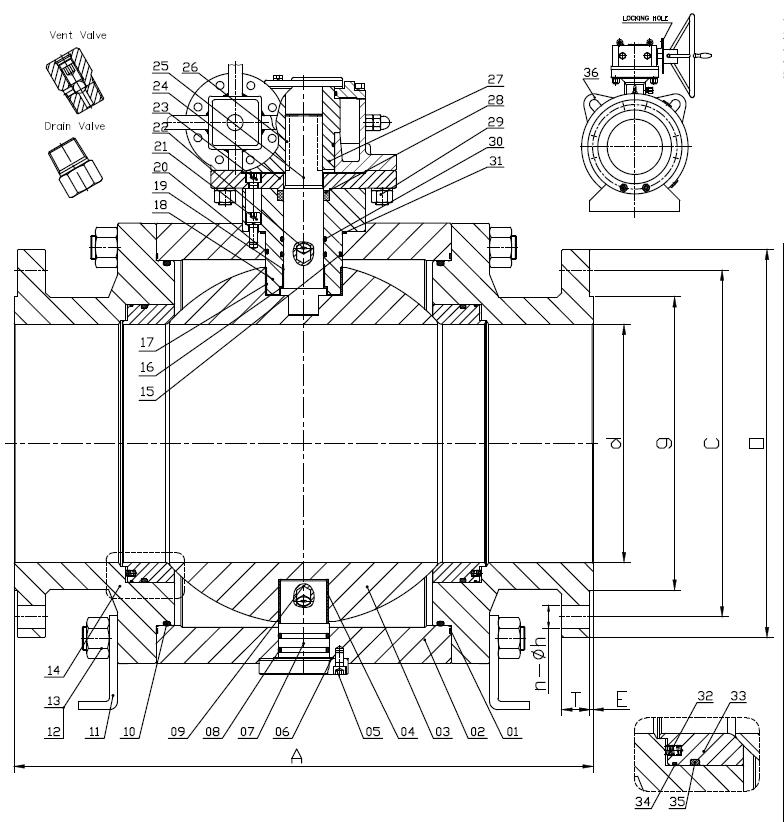

| MAIN PARTS AND MATERIALS | |||||

| NO | PART NAME | MATERIAL | NO | PART NAME | MATERIAL |

| 01 | Gasket | SS304+GRAPHITE | 22 | Vent valve | A105+Zn |

| 02 | Body | ASTM-A105N | 23 | Screw | A193-B7M |

| 03 | Ball | A182-F316+TCC | 24 | Correcting plate | ASTM-A105N |

| 04 | Sliding bearing | SF-1 | 25 | Stem | A479-XM-19 |

| 05 | Screw | A193-B7M | 26 | KEY | ASTM-1045 |

| 06 | Gasket | SS304+GRAPHITE | 27 | gear | COMBINATION |

| 07 | TRUNNION | A105-ENP | 28 | Packing | GRAPHITE |

| 08 | "O"Ring | FKM-A75 | 29 | Pin | A276-410 |

| 09 | Draln valve | A105-Zn | 30 | Nut/Stud | A194-2HM/A193-B7M |

| 10 | "O"Ring | FKM-A75 | 31 | Gasket | SS304+GRAPHITE |

| 11 | Frame | ASTM-1025 | 32 | Spring | INCONEL X-750 |

| 12 | Nut | A194-2HM | 33 | Seat | A182-F316+TCC |

| 13 | Stud | A193-B7M | 34 | "O"Ring | FKM-A75 |

| 14 | Bonnet | ASTM-A105N | 35 | "O"Ring | FKM-A75 |

| 15 | "O"Ring | FKM-A75 | 36 | Hanging board | ASTM-A1045 |

| 16 | Thrust washer | PTFE | 37 | ||

| 17 | Sliding bearing | SF-1 | 38 | ||

| 18 | Cover | ASTM-A105N | 39 | ||

| 19 | Sliding bearing | SF-1 | 40 | ||

| 20 | "O"Ring | FKM-A75 | 41 | ||

| 21 | Screw | A193-B7M | 42 | ||

1. What is trunnion mounted ball valve?

The closing part of the Trunnion Mounted Ball Valve is a sphere, and the sphere rotates around the center line of the valve body to open and close a valve. It is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. Trunnion Mounted Ball Valve has a floating valve seat. After being pressurized by the medium, the valve seat moves, so that the sealing ring is tightly pressed on the ball to ensure the sealing. Bearings are usually installed on the upper and lower shafts with the ball, and the operating torque is small, which is suitable for high-pressure and large-diameter valves.

2. What is the difference between trunnion and floating ball valves?

Trunnion Ball Valves Compared to floating ball valves, trunnion ball valves are suitable for high pressure applications. The torque of the fixed ball valve is one-point less than that of the floating ball valve, so it is more labor-saving to use. Trunnion ball valves have higher operating costs than free-floating ball valves.

Learn more.

3. How to use Trunnion Mounted Ball Valve?

(1) Make sure that the pipeline and valve have been flushed before operation.

(2) The operation of the trunnion mounted ball valve is completed by driving the valve stem to rotate according to the size of the input signal of the actuator: when it rotates 1/4 turn (900) in the forward direction, the valve is turned off. The valve opens when reversed 1/4 turn (900).

(3) When the direction indicating arrow of the actuator is parallel to the pipeline, the valve is open; when the indicating arrow is perpendicular to the pipeline, the trunnion mounted ball valve is closed.

All above knowlege supplied by our enginner, if you need pls contact us.

Tel:

+86 138 6861 8624

Tel(日本語対応):

+86 181 0553 1755

Email:

Email(日本語対応):

Keywords: Trunnion Mounted Ball Valves Manufacturer API 600 Gate Valve Manufacturer Types of Plug Valves Class 300 LB Plug Valve Lubricated VS. Non-Lubricated Plug Valves: What You Need to Know What is the standard API for gate valves? Control Valves: Everything You Need to Know 5 Best Plug Valves Manufacturers and Suppliers Diaphragm Valve API 6D Ball Valve Manufacturers Flanged End Ball Valves - API 6D The Difference between API 608 and API 6D Valve Standard

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More