Standard

Design and manufacture in accordance with API 6D

Face to face dimensions to ANSI B16.10

End dimensions to ANSI B16.5

Valve Test to API598

CNM VALVE, a leading flanged floating ball valve manufacturer, is proud to present the API 6D Floating Ball Valve. Designed for reliable flow control, this valve is an excellent choice for a wide range of applications. With sizes ranging from 1/2" to 10", our flanged floating ball valve offers exceptional performance and durability.

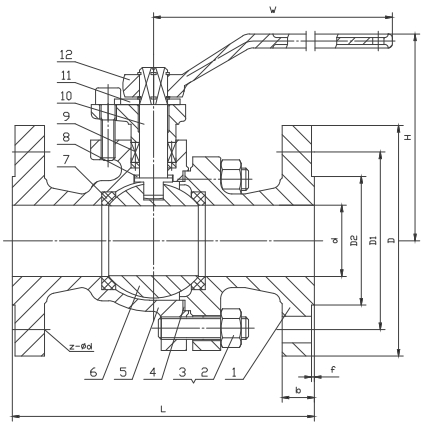

| NO | Part name | material |

| 1 | Body | CF8/CF8M |

| 2 | Bonnet Bolt | ASTM A193 Gr.B7 |

| 3 | Bonnet Bolt Nut | ASTM A194 Gr.2H |

| 4 | Gasket | PTFE |

| 5 | Cover | ASTM A216-WCB |

| 6 | Ball | ASTM A182-F304 |

| 7 | Seat Ring | PTFE |

| 8 | Thrust Ring | PTFE |

| 9 | Packing | PTFE |

| 10 | Stem | ASTM A276-304 |

| 11 | Stopper | ASTM A36 |

| 12 | Handle | ASTM A216 WCB |

| Type connection | Flanged |

| Size | From 1/2" to 10" |

| Pressure | From 150LBS to 600LBS |

| Material | Stainless steel/CF8, Cast steel / WCB |

| unit:mm | ||||||||||

| DN | d | L | H | W | D | D1 | D2 | b | F | z-Фd |

| 1/2" | 14 | 108 | 59 | 130 | 89 | 60.5 | 35 | 10 | 1.6 | 4-16 |

| 3/4" | 19 | 117 | 63 | 130 | 99 | 69.9 | 43 | 10.5 | 1.6 | 4-16 |

| 1" | 25 | 127 | 75 | 160 | 108 | 79.2 | 51 | 11.5 | 1.6 | 4-16 |

| 1-1/4" | 32 | 140 | 85 | 200 | 117 | 88.9 | 64 | 13 | 1.6 | 4-16 |

| 1-1/2" | 38 | 165 | 95 | 230 | 127 | 98.6 | 73 | 14.5 | 1.6 | 4-16 |

| 2" | 49 | 178 | 155 | 260 | 152 | 120.5 | 92 | 16 | 1.6 | 4-19 |

| 3" | 76 | 203 | 195 | 280 | 190 | 152.4 | 127 | 19.5 | 1.6 | 4-19 |

| 4" | 100 | 229 | 215 | 320 | 229 | 190.5 | 157 | 24 | 1.6 | 8-19 |

| 6" | 150 | 394 | 275 | 720 | 279 | 241.3 | 216 | 25.5 | 1.6 | 8-22 |

| 8" | 201 | 457 | 345 | 850 | 343 | 298.5 | 270 | 29 | 1.6 | 8-22 |

| 10" | 252 | 533 | 495 | 1000 | 406 | 362.0 | 324 | 30.5 | 1.6 | 12-25 |

Structural features

Float ball valves are superior products developed upon the advanced technology home and abroad. Provided with updated designs ideas, they meet the requirements on safety and convenience in general industrial standards.

Anti-blow out sructures of valve stem

When medium passes through the valve, the pressure in valve body may possibly push the stem out or when the valve is repair, if there is pressure in the middle cavity, the stem or medium seems to easily blow out upon disassembling the valve, which can cause injuries to human beings. To prevent these possibilities, a dummy club is placed at the lower part of the stem. In this way, even if there is fire, packing and thrust bearing are burnt or packing is damanged due to other causes, the pressure of medium in valve body will make the dummy club of valve stem in close contact with the upper seal face of valve body, thus to prevent medium leaking out from the damaged packing position.

Switch indication of hand operated float ball valve

As the moving parts of valve, ball,valve stem and handle are an assembly unit. The head of valve stem is shaped a diploid, thus to easily distinguish whether valve is in the 'ON' position or ' OFF' position from handle position. When handle or stem diploid is in parallel with the pipe axis, valve is in 'ON' position; when handle or stem diploid is vertical to the pipe axis, valve is in 'OFF' position.

Antistastic device

When operating the valve, te friction between the ball and the nonmetal seat, like PTFE etc. will produce electrostatic charge that can be accumulated on the ball. To prevent static spark, an antistatic device is placed on the valve to drive the eletric charge accumulated on the ball from the static channel between the ball and the stem, or between the stem and valve body.

Valve locking device

To prevent misoperation, the fully opened or closed position of valve can be locked up, especially when valves are mounted outdoors or when valves are not allowed to be opened or closed by technical process. To prevent misoperation by other persons, it seems very important to have valve position locked up. There by, lockhole locating tb is designed if requested by users to meet the technological requirement or users.

As a reputable API 6D Floating Ball Valve manufacturer, CNM VALVE is committed to delivering top-quality products that meet stringent industry standards. Our API 6D Floating Ball Valve offers exceptional performance, durability, and precise flow control. With a focus on customer satisfaction, we strive to provide reliable solutions that meet your specific requirements.

Contact CNM VALVE today to learn more about our API 6D Floating Ball Valve and how it can benefit your applications. Trust in our expertise and experience for all your valve needs.

Tel:

+86 138 6861 8624

Tel(日本語対応):

+86 181 0553 1755

Email:

Email(日本語対応):

Keywords: Trunnion Mounted Ball Valves Manufacturer API 600 Gate Valve Manufacturer Types of Plug Valves Class 300 LB Plug Valve Lubricated VS. Non-Lubricated Plug Valves: What You Need to Know What is the standard API for gate valves? Control Valves: Everything You Need to Know 5 Best Plug Valves Manufacturers and Suppliers Diaphragm Valve API 6D Ball Valve Manufacturers Flanged End Ball Valves - API 6D The Difference between API 608 and API 6D Valve Standard

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More

CNM VALVE is your first choice for total valve solution. CNM VALVE is a total valve solution supplier which specializes in R&D, design, manufacture, sales, and service. View More